Waterjet equipments are surprisingly intricate and strong at the same time. When we consider typical cutting process, we'll think of scissors or saw. Cutting a piece of paper with a scissor is a relatively easily process. You can make clean cuts in almost any shape and form when cutting a piece of paper since the material is so light and flexible. Papers are often thin enough that merely pushing your scissor across can do the job.

Trying to make the same type of cut on a piece of wood would be more challenging. Using a hand saw to slowly cut through the wood in the shape you desire can be a long and difficult process. Process becomes easier and more manageable when you use electric saws or table saws which allow you to control the material better. What makes cutting wood more difficult than cutting a piece of paper is the fact that you have to exert a large force in order to make a cut. When you are applying force, it is very difficult to control that force to make a precise cut through and through.

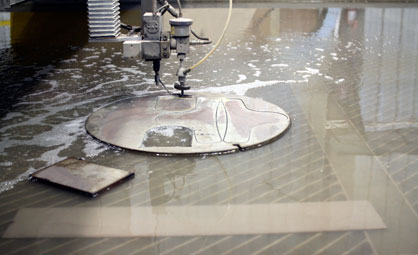

Metal fabrication is virtually impossible with a saw, let alone a scissor. Cutting aside, slabs of metals are challenging enough to just maneuver around. Waterjet makes cutting metals easy as cutting wood on a table saw. By applying tremendous amount of force on a small stream of water, waterjets are able to puncture through solid materials and end up cutting them as you move the material or waterjet nozzle around. In fact, the stream of water can be controlled to be just 0.003 inches (or 0.076 millimeters) thin, allowing you to create the most intricate cut on the hardest of materials.

Waterjets basically offer the best of both worlds, offering great power and accuracy at the same time. When you are chopping wood with an axe, you are applying significant force at the sacrifice of accuracy. You are able to chop at the general proximity but it would never be so accurate that you will be cutting furniture with an axe. Waterjets can apply a even greater force while being precise enough to create hairline cuts on the toughest materials. This has great industrial use and potential since almost any part can be intricately crafted using waterjets.

When you take a look at a typical consumer electronic appliance, it will often be composed of parts which are made of metal, plastic, glass, rubber and etc. Waterjets are flexible enough to be able to cut through all the mentioned materials, which makes it a one stop solution for many industries out there. Rather than requiring multiple machinery to cut various materials, a single waterjet facility can be used to provide all the fabrication services that a company might need. From versatility to efficiency, waterjets offers significant advantage to the industries who have adapted its use.